Home / About Us

- Specialized in pipeline connection

- Hongli Pipe Machinery ---To be the leader of pipe machinery in the world

- Company Profile

- Hongli Pipe Machinery, established in 1986, was a company with more than 30 years of experiences in R&D and manufacturing pipe machines and tools.

With brands of Tiger King, Mambacleaning, Hongli is on his way of understanding and providing professional solutions of the project problems our customers facing. Tiger King is the brand for domestic market and it occupies 40% of the market share. Mambacleaning is a brand for developing for drain cleaning machines.

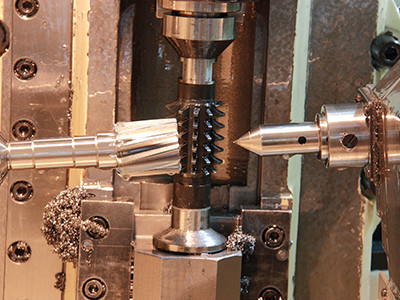

- Hongli Pipe Machinery, specialized in pipeline connection, has been paying his attention to the development of the cutting tools and spare parts of the pipe machines and tools. Hongli members believe great cutting spares such as pipe threading dies and cutting wheels make your work fast and easy. Hongli has our own workshops for pipe threading manufacturing, heat treatment and metal processing.

Now Hongli is also preparing to help customers improve project efficiency by using more efficient and intelligent motors to improve machine efficiency. Portable cordless pipe threading tools will also be launched soon.

Why Choose Hongli Pipe Machinery

- 1Rich Product Line

- 10 series of machines and tools with more than 300 models of products, involving pipe threading, pipe cutting and beveling, pipe grooving, pipe drain cleaning, pipe bending, pipe welding, and high pressure washing and pipe installation tools.

- Pipe Threading

- Pipe Cutting

- Pipe Bending

- Pipe Cleaning

- Pipe Grooving

- Pipe Hole Cutting

- Pipe Welding

- Pipe Beveling

- Pipe Installation Tools

- 2Tool Processing Assurance

- Own workshops for heat treatment and threading dies manufacturing makes the OEM and ODM available and also makes the quality controllable. Some Hongli dies are compatible with famous brands abroad such as RIDGID, ROTHENBERGER, REX and so on. Hongli pipe cutting wheels are interchangeable with REED.

- 3Experience & Development Path

- 36 years of developing and manufacturing experience for pipe machines and tools.

DEVELOPMENT PATH

- 2023The factory was upgraded and an automated production workshop was added to improve product production efficiency.

- 2020Successfully R&D SQ30-2C and SQ30A Pipe Threaders, AG100 drum drain cleaning machine, H18S H22S rotary pipe cutters. Updating alloy material of threading dies.

- 2018Successfully R&D the automatic pipe grooving machine.

- 2017Successfully R&Dthe drain cleaning machines A75, A150.

- 2016Successfully R&D the large caliber explosion-proof pipe cutter..

- 2015Successfully R&D the portable fire pipe hole cutter.

- 2014SuccessfullyR&D the pipe hole cutter with big power, used in Subway Fire Engineering.

- 2013Established sales company - Hangzhou Guanba Machinery Import &Export Co.,Ltd.

- 2012Developed high-end threading die which was service in the field of oil pipelines, the only domestic manufacturer to get involved in this field.

- 2011SQ30-2B portable pipe threaderwas included in the National Torch Program.

- 2010Became the National high-tech enterprises.

- 2009Model30/50/100 pipe threading machine got the CSA certification.

- 2007Successfully R&D in succession high efficient pipe threading machine SQ50D, SQ50E, SQ50F, SQ80C1, SQ100F.

- 2006Successfully R&D the first pipe cutting machine.

- 2005Successfully R&D the first pipe grooving machine.

- 2003EstablishedHangzhou Hongli Pipe Machinery Co. Ltd.

- 1998Model 50/ 80/100 pipe threading machines got CE, GS certification by GermanyRhine.

- 1997Successfully R&D China’s first handheld SQ30 pipe threader.

- 1995EstablishedHangzhou Huaxing Machinery Co. Ltd.

- 1988Hangzhou Huaxing Machinery factory was founded, successfully R&D the first pipe threading machine.

Expand More

Collapse history

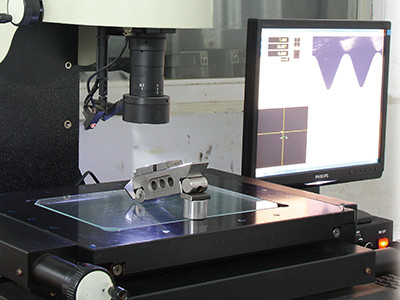

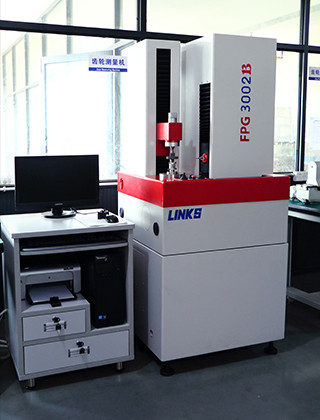

- 4Quality Control

Normative Inspection Process

-

- 1Outsourcing Inspecting

-

- Bought-in Raw Material

- Bought-in Components

-

- 2Warehouse Entering

-

- Checking & Testing

- Metal Processing

-

- 3Parts Painting

-

- Standard Color

- OEM Color

-

- 4Painting Parts Inspecting & Testing

-

- Bought-in Raw Material

- Bought-in Components

-

- 5Assembly

-

- Parts Assembly

- General Assembly

-

- 6Packaging

-

- Standard Packaging

- OEM Packaging

-

- 7Packaging Producing

-

- Outsourcing Cartons /BMC

- Plywood Case Producing

-

- 8Machines & Packages Inspecting

-

- Quality & Quantity Inspection

- Product Photos Taking

-

- 9Finished Goods Warehouse Entering

-

- Bought-in Raw Material

- Bought-in Components

- 5Spare Parts Inventory

Complete spare parts inventory can supply you the main spares timely. For some common spare parts, Hongli can even send out within one day after all your confirmation.

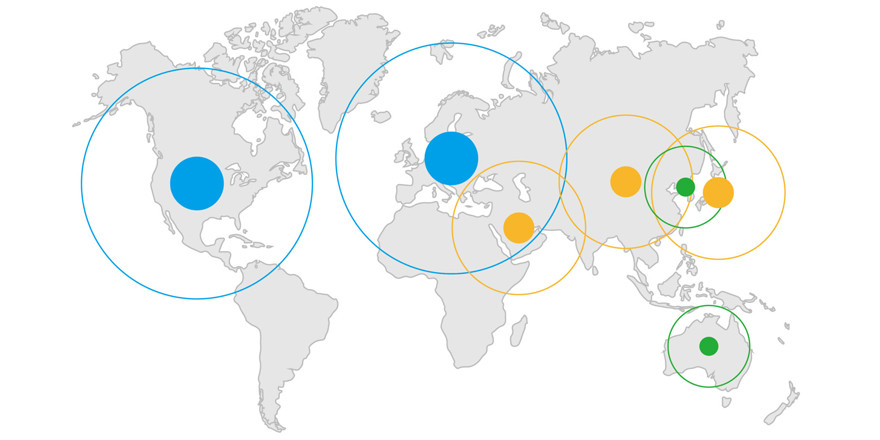

- 6Market Distribution

- Hongli has been in business since 1986 as Hangzhou Huaxing Machinery Factory. We have grown to be one of leading manufacturing companies of pipe threading machines and pipe grooving machines and pipe cutting machines and pipe hole cutters in China with many customers around the globe.

- factory

- Hongli Pipe Machinery, established in 1986, was a company with more than 30 years of experiences in R&D and manufacturing pipe machines and tools.

- service

- Hongli Pipe Machinery provide services in product OEM, order inspection, after sales training and some other parts you worry about.

Please send your message to us

- *Title

- *Content

Pipe threading machine

Pipe threading machine Portable Pipe Threader

Portable Pipe Threader Professional Stationary PipeThreading Machine

Professional Stationary PipeThreading Machine Economy Stationary Pipe Threading Machine

Economy Stationary Pipe Threading Machine Threading spare parts

Threading spare parts Pipe grooving machine

Pipe grooving machine pipe cutting machine and tool

pipe cutting machine and tool Pipe cutting machine

Pipe cutting machine Hole cutting and drilling

Hole cutting and drilling Hinged pipe cutter

Hinged pipe cutter Rotary Pipe Cutter

Rotary Pipe Cutter Pipe drain cleaning machine

Pipe drain cleaning machine Pipe installation tools

Pipe installation tools High pressure washing machine

High pressure washing machine Pipe beveling machine

Pipe beveling machine Pipe bending machine

Pipe bending machine Plastic welding machine

Plastic welding machine About HL

About HL Company Certificate

Company Certificate Company Team

Company Team OEM Service

OEM Service FAQ

FAQ Video Center

Video Center